Technologies

EMI’s Advanced Cutting-Tool Technologies

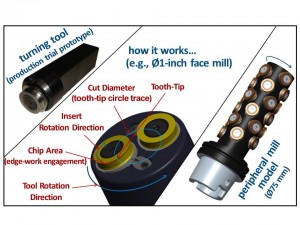

RotanTM – Rotary-Insert Cutting Tools

(U.S. Patents Pending; E.U. Patent Pending)

EMI-developed Rotan rotary tangential-mount technology brings all the benefits of a rotating insert into perfect alignment with semi-finish and finish machining. All the benefits of rotary-insert machining — continuous indexing of the full circumference of the insert’s cutting edge, no potential for notch wear, management of heat, and smart use of the large insert radius — plus application strategy and special tooling hardware enhancements that produce fine finish with no visual artifacts of insert rotation. Rotary-insert machining can provide up to 90% reduction in cycle time and projected increases in tool life (servicing interval) of 50x or more.

MQuIC™

(U.S. Patents Issued)

EMI’s Micro-Quantity Internal Cooling (MQuIC™) technology offers extended tool life in finish-machining of difficult-to-machine materials. MQuIC™ technology addresses thermally induced wear by concentrating a cooling medium close to the process heat source.

Micro-Jet Array

(U.S. Patent Issued)

EMI’s Micro-Jet Array (MJA) precision-cooling technology is derivative of the MQuIC™ concept, except that the coolant is applied at micro-scale via jets originating external to the insert rather than from within the insert.

EMI Technologies on the Horizon

ThikCoat™

(U.S. Patent Issued)

EMI’s ThikCoat™ technology, having recently completed the

commercial feasibility stage under a Phase-I SBIR project, addresses abrasive wear by creating a

significantly thicker hard coating on a substrate than is traditionally possible.

commercial feasibility stage under a Phase-I SBIR project, addresses abrasive wear by creating a

significantly thicker hard coating on a substrate than is traditionally possible.

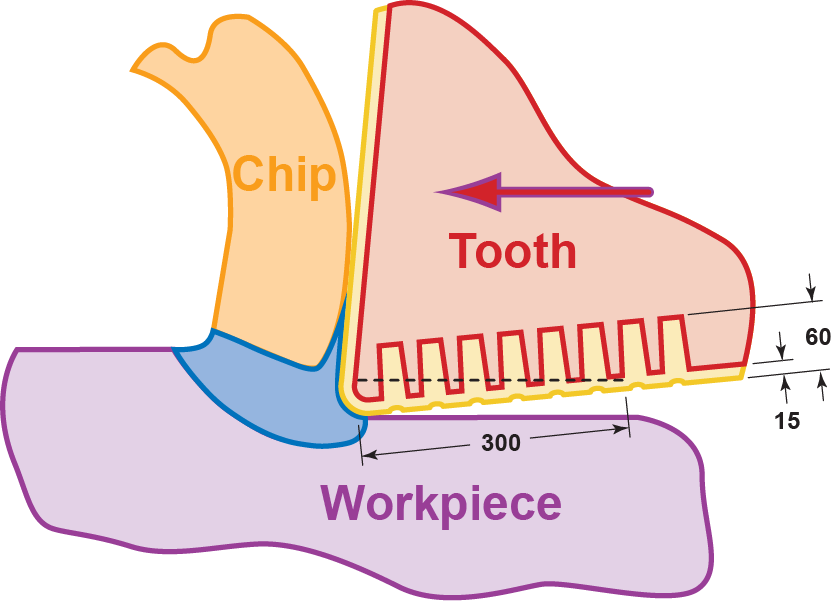

Universal Chip Breaking:

Currently in the technical feasibility stage, EMI’s Universal Chip Breaking (UCB) technology offers a single cutting insert geometry for all cutting classes (rough, medium, finish).

CHiPPS™

(U.S. Patent Issued)

Applications include vehicular storage for hydrogen- and CNG-based transportation and oxygen/air storage for home medical oxygen patients…

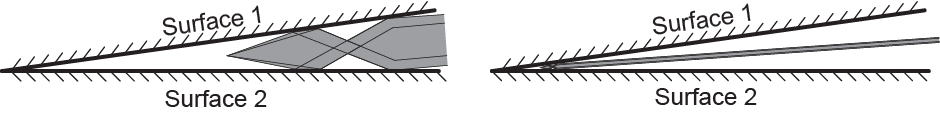

EMI’s Micro-Jet Array (MJA) precision-cooling technology is derivative of the MQuIC™ concept, except that the coolant is applied at micro-scale via jets originating external to the insert rather than from within the insert. Multiple, adjacent, 50-100 μm nozzles (a one-dimensional nozzle array) produce micro-scale jets that penetrate deeply into the narrowly opening space between the chip and the rake face, and also between the flank face and machined surface. This produces significantly better penetration to the heat sources than does a typical 1 mm diameter jet to the chip’s backside and rake face. The intent is not chip breaking, only cooling. The deep penetration is enabled by the size of the jets, which allows each jet to maintain its integrity much deeper into the narrow spaces noted. Because they are arranged in an array, they evenly apply coolant along the entire cutting edge, and unlike a sheet-like jet alternative, they allow liquid coolant, and any vaporized coolant, to exit the zone via reverse-flow between the jet streams that are entering the zone. There are special features on the insert at the rake face and/or the flank that enable and/or enhance the micro-jet penetration.

EMI’s Micro-Jet Array (MJA) precision-cooling technology is derivative of the MQuIC™ concept, except that the coolant is applied at micro-scale via jets originating external to the insert rather than from within the insert. Multiple, adjacent, 50-100 μm nozzles (a one-dimensional nozzle array) produce micro-scale jets that penetrate deeply into the narrowly opening space between the chip and the rake face, and also between the flank face and machined surface. This produces significantly better penetration to the heat sources than does a typical 1 mm diameter jet to the chip’s backside and rake face. The intent is not chip breaking, only cooling. The deep penetration is enabled by the size of the jets, which allows each jet to maintain its integrity much deeper into the narrow spaces noted. Because they are arranged in an array, they evenly apply coolant along the entire cutting edge, and unlike a sheet-like jet alternative, they allow liquid coolant, and any vaporized coolant, to exit the zone via reverse-flow between the jet streams that are entering the zone. There are special features on the insert at the rake face and/or the flank that enable and/or enhance the micro-jet penetration.